It is hard to open a brewery. Imagine opening one during a pandemic. There have been a few brave souls in Alberta who have done just that in the past year or so. One of them is Spruce Grove’s first ever brewery, Talking Dog Brewing.

I did a profile of them on my CBC column a few weeks back. You can listen to it here. I thought I would supplement that piece with some thoughts here.

Talking Dog is Paul and Jennifer Houle, literally. The brewery is operated exclusively by the two of them. But I think they can handle it – they are a pretty smart duo. Paul is an environmental chemist and Jennifer is a biologist. They also have three kids and Paul is an avid triathlete. Did I mention they have both kept their day jobs? Yeah, I think you get what I am saying.

A number of things make Talking Dog stand out, aside from its over-achieving owners. One that particularly caught my attention was their environmentally-conscious brewhouse design. It is a Brewha BIAC 7-barrel one-vessel system. It is a basically a commercial brew-in-a-bag system. The mash, sparge, boil and fermentation all take place in one vessel. There are two advantages to this setup, Paul says. “Breweries use a lot of water,” he notes. “Most breweries use six to seven litres of water to make one litre of beer. our system uses two litres of water for one litre of beer”. Water used for cooling and cleaning can be re-used.

The brewery also eschews any chemicals. “Everything basically gets sanitized during the boil so I can avoid harsh caustic chemicals”, Paul says. The system even avoids glycol, using water to cool the vessel.

The second advantage to his brewhouse is its portability – every vessel is on wheels. “I don’t want to be married to any specific space. I can wheel everything out the back door and onto a truck. Nothing is hard plumbed and the system is electric”.

While they are currently happy with their space in a retail strip mall on the edge of downtown, they are renting and Paul dreams of owning his own space. “We hate renting. If we could own a place that is our preferred option”.

Being the first brewery in the sleep satellite community 30-minutes west of Edmonton, the Houles know part of their job is beer education. “People are dipping their toe in the craft beer water”, says Paul. “We get people asking ‘what is craft beer?’ So it becomes about education”.

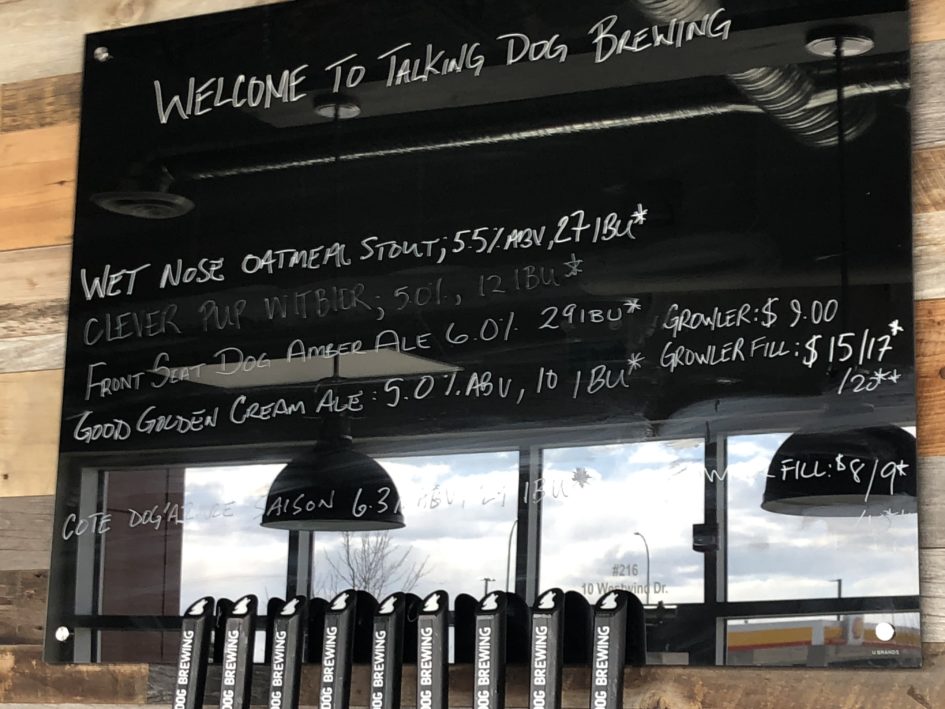

Paul, who brews early in the morning before starting his day job, has an approach to beer that is well-suited for such a project. “Classic styles are my happy place”, he notes, adding that people won’t see a lot of fruit or hazy beer from Talking Dog. The three core beer are Good Golden Cream Ale, Front Seat Dog Amber Ale and Working Dog IPA. Plus they are committed to a regular rotating saison.

Naturally the beer names are dog-themed, as the Houles are huge dog lovers. The brewery name comes from a golden retriever they once had who would sit on the back deck and have conversations with other dogs in the neighbourhood, barking, waiting for a reply and then barking again.

The other thing to know about Talking Dog is that they are a local brewery. You are going to have to go to them. “Our purpose for living is to service the taproom. We do sell kegs here or there, but the primary purpose is the taproom” warns Paul. COVID-19 did lead them to start canning their core line-up but even that will be mostly taproom focused. “The majority of cans will be sold as off-sales”.

They have no intentions of growing big. “We want to manage our own growth. A core tenet of ours is to be masters of our domain” observes Paul. “It is just Jenn and I. No other investors. We don’t want to put ourselves in position that we don’t love brewing anymore”.

Despite the quiet beginnings due to COVID, I suspect Talking Dog will be making some noise in Alberta in the years to come.

June 25, 2021 at 11:03 AM

Congrats and good luck to Talking Dog!

I wanted to comment on the “Most breweries use six to seven litres of water to make one litre of beer”. When I started in the beer business in 1975 (!) the Carling O’Keefe plant in Saskatoon used water at a ratio of 18-to-1. The majority of this was attributed to the bottle washer (rinse water), an inefficient (1948 model) flood pasteurizer, and water and brine cooling (since changed to glycol and ammonia). With increased emphasis on kegs and cans (sorry Jason), and newer, more energy efficient equipment, that ratio has dropped. When I retired last year, Great Western was down to about a 9-to-1 ratio. Not too bad for a 93 year old brewery.